Formwork

This presentation presents an introduction of formwork systems used in construction, focussing on slab, beam, and column casting. It introduces modular and reusable formwork methods that improve construction efficiency, quality, and safety while lowering labour and material waste. The emphasis is on comparing conventional lumber formwork to modern aluminium and system formwork, highlighting advantages such as faster construction, greater surface polish, and reusability. Key topics discussed include shuttering material, props, tie rods, drop heads, and safety precautions. The presentation also includes best practices and safety requirements for efficient and secure on-site operation.

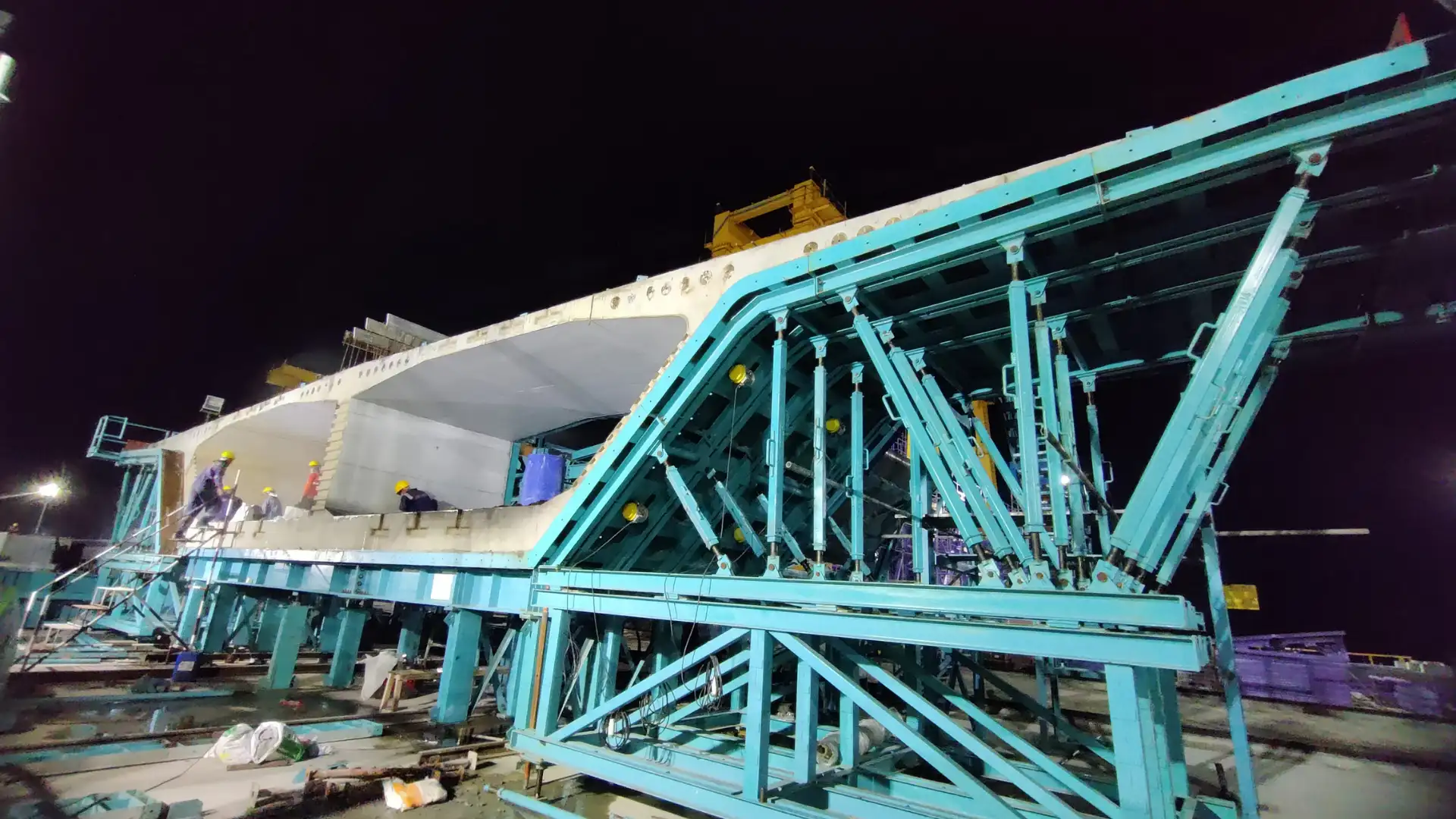

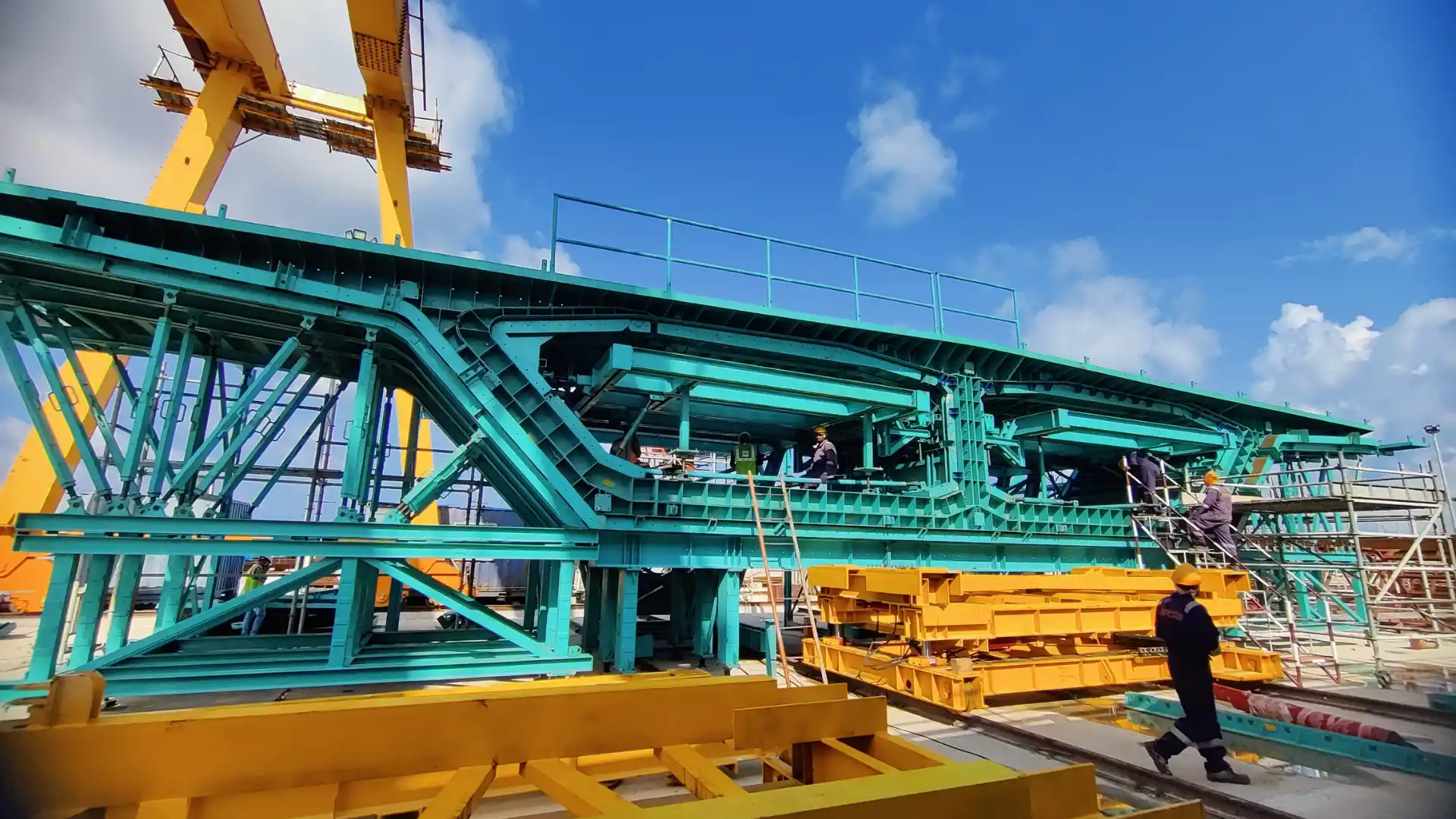

M/s. Afcons Infrastructure Limited | Greater Male Connectivity, Maldives Project

Metalmeccanica successfully provided 807 MT of 25.37-meter and 17.80-meter-wide Short Line segments to M/s. Afcons Infrastructure Limited is part of the famous Greater Malé Connectivity Project in the Maldives. The shipment contained two complete sets of moulds, which aided the building of one of the region’s most important infrastructure projects.

Description:

Client: M/s. Afcons Infrastructure Limited

Project: Greater Male Connectivity, Maldives Project

Product: Short Line 17.80 Mtr wide segment

Quantity: 287 MT supply for 2 sets of mould

Product: Short Line 25.37 Mtr

Quantity: 520.00 MT supply for 3 sets of mould

L&T Construction, MAHSR C3 (High Speed Rail Project),

Metalmeccanica provided 423 MT of Short Line segments, each 11.32 metres wide, to M/s. Afcons Infrastructure Limited for the Ahmedabad Metro Link Rail Project Phase II (GMRC Project). The delivery included three complete sets of short line moulds, which will help to advance this critical urban transit infrastructure.

Description:

Client: L&T Construction

Project: MAHSR C3 (High Speed Rail Project)

Product: Pier with Pier Cap

Quantity: 825 MT – Supplied 13 Sets of Pier Formworks

M/s. Afcons Infrastructure Limited | Ahmedabad Metro Link Rail Project Phase II (GMRC Project)

Metalmeccanica provided 423 MT of Short Line segments, each 11.32 metres wide, to M/s. Afcons Infrastructure Limited for the Ahmedabad Metro Link Rail Project Phase II (GMRC Project). The delivery included three complete sets of short line moulds, which will help to advance this critical urban transit infrastructure.

Description:

Client: M/s. Afcons Infrastructure Limited

Project: Ahmedabad Metro Link Rail Project Phase II (GMRC Project)

Product: Short Line 11.32 Mtr wide

Quantity: 423 MT supply for 3 sets of shortline mould

SMC Infrastructures Private Limited | Mental Hospital Flyover, Thane

Metalmeccanica supplied SMC Infrastructures Private Limited with 250.48 MT of formwork and staging for the Cast in Situ Voided Slab for the Thane Mental Hospital Flyover Project. This specialised formwork solution allowed for the efficient and precise construction of a critical section of the flyover.

Description:

Client: SMC Infrastructures Private Limited

Project: Mental Hospital Flyover, Thane

Product: Cast in Situ Voided Slab (Formwork with Staging)

Quantity: 250.48 MT

L&T Construction | MAHSR C4 & C3 (National High Speed Rail Project)

Metalmeccanica supplied L&T Construction with 825 MT of pier formwork, including integrated pier and pier cap configurations, for the MAHSR C3 (Mumbai-Ahmedabad High Speed Rail) Project. The scope included 13 complete sets of precision-engineered formworks to support the construction of India’s pioneering high-speed rail corridor.

Description:

Client: L&T Construction

Project: MAHSR C4 & C3 (National High Speed Rail Project)

Product: Pier with Pier Cap

Quantity: 1255 MT – Supplied 21 Sets of Pier Formworks

Dineshchandra R. Agarwal Infracon (I) Pvt. Ltd. | MAHSR C7 (High Speed Rail Project)

Metalmeccanica supplied 3 sets of Segmental Longline Beds and one complete set of Pier with Pier Cap Shuttering System for India’s Mumbai–Ahmedabad High Speed Rail (MAHSR) C7 package. Designed for precision and durability, the custom-engineered system enhances efficiency and safety in the casting process, supporting the elevated bridge works of India’s first bullet train corridor.

Description:

Client: Dineshchandra R. Agarwal Infracon (I) Pvt. Ltd.

Project: MAHSR C7 (Mumbai–Ahmedabad High Speed Rail Project)

Product Supplied: Pier with Pier Cap Shutter

Quantity: 122.64 MT – 1 Set Supplied

Dineshchandra R. Agarwal Infracon (I) Pvt. Ltd.,

Metalmeccanica supplied L&T Construction with 825 MT of pier formwork, including integrated pier and pier cap configurations, for the MAHSR C3 (Mumbai-Ahmedabad High Speed Rail) Project. The scope included 13 complete sets of precision-engineered formworks to support the construction of India’s pioneering high-speed rail corridor.

Description:

Client: L&T Construction

Project: MAHSR C3 (High Speed Rail Project)

Product: Pier with Pier Cap

Quantity: 825 MT – Supplied 13 Sets of Pier Formworks